Get a presentation of RAS fish farming business

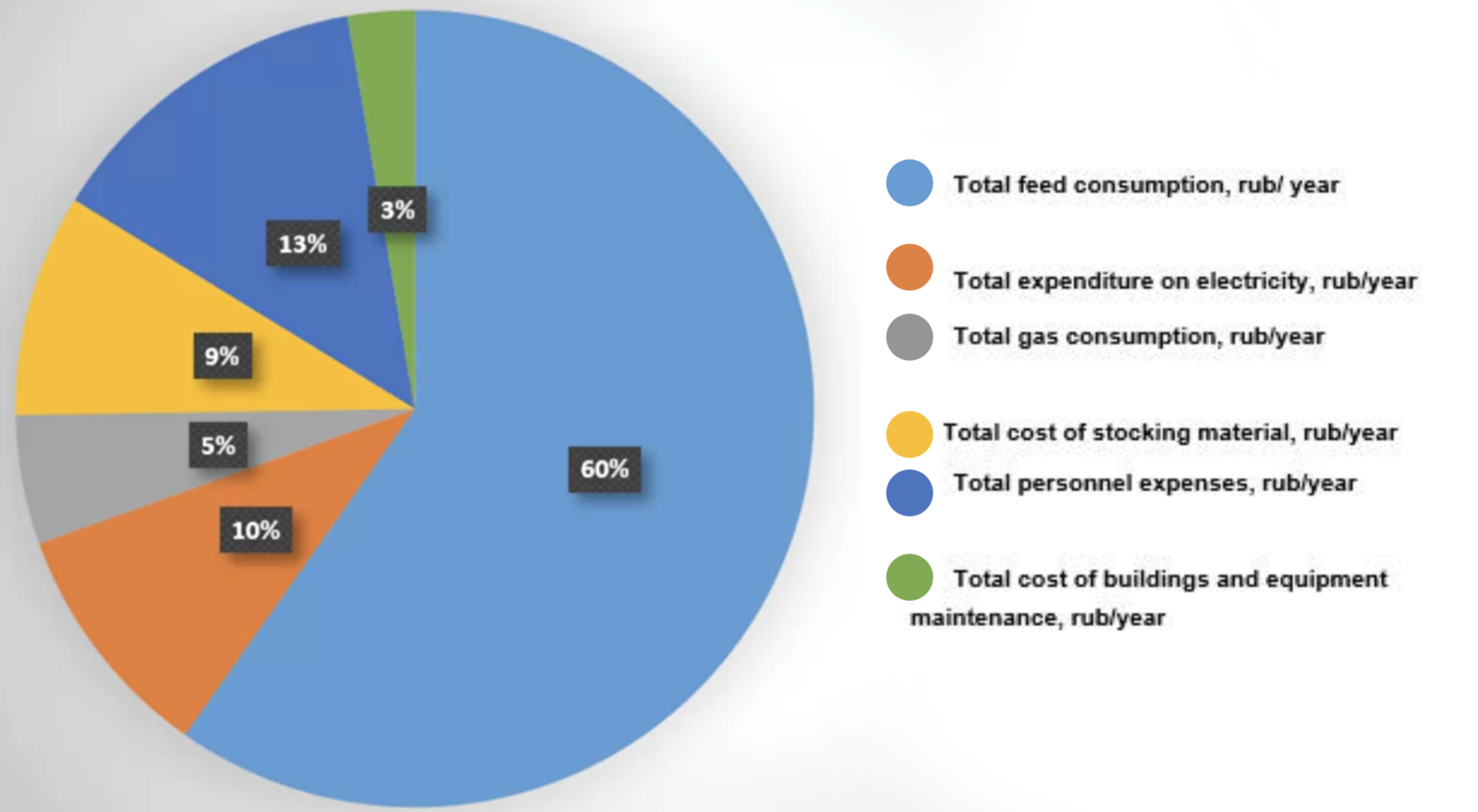

- Expenses and prime costs

- Profitability and payback

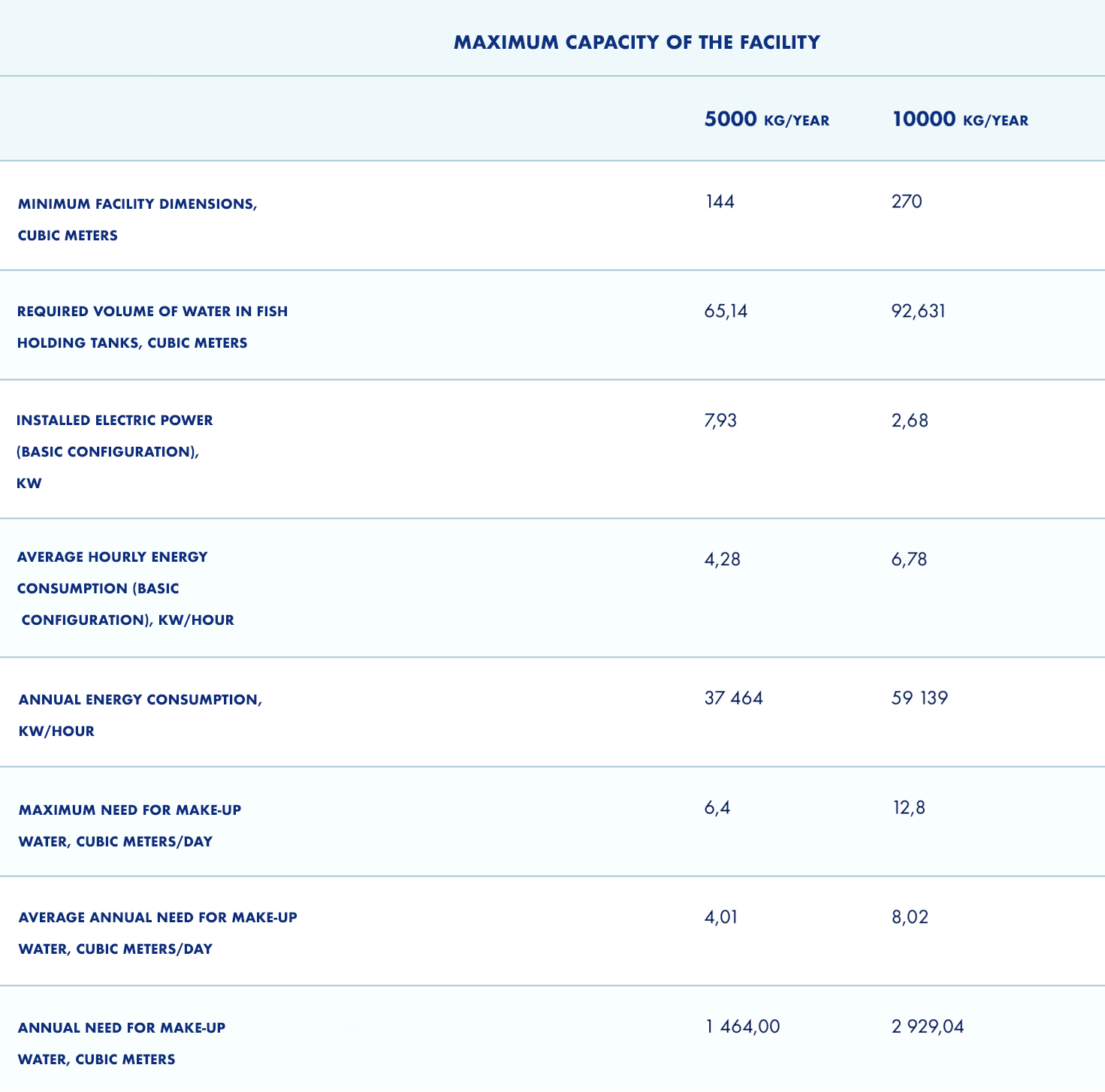

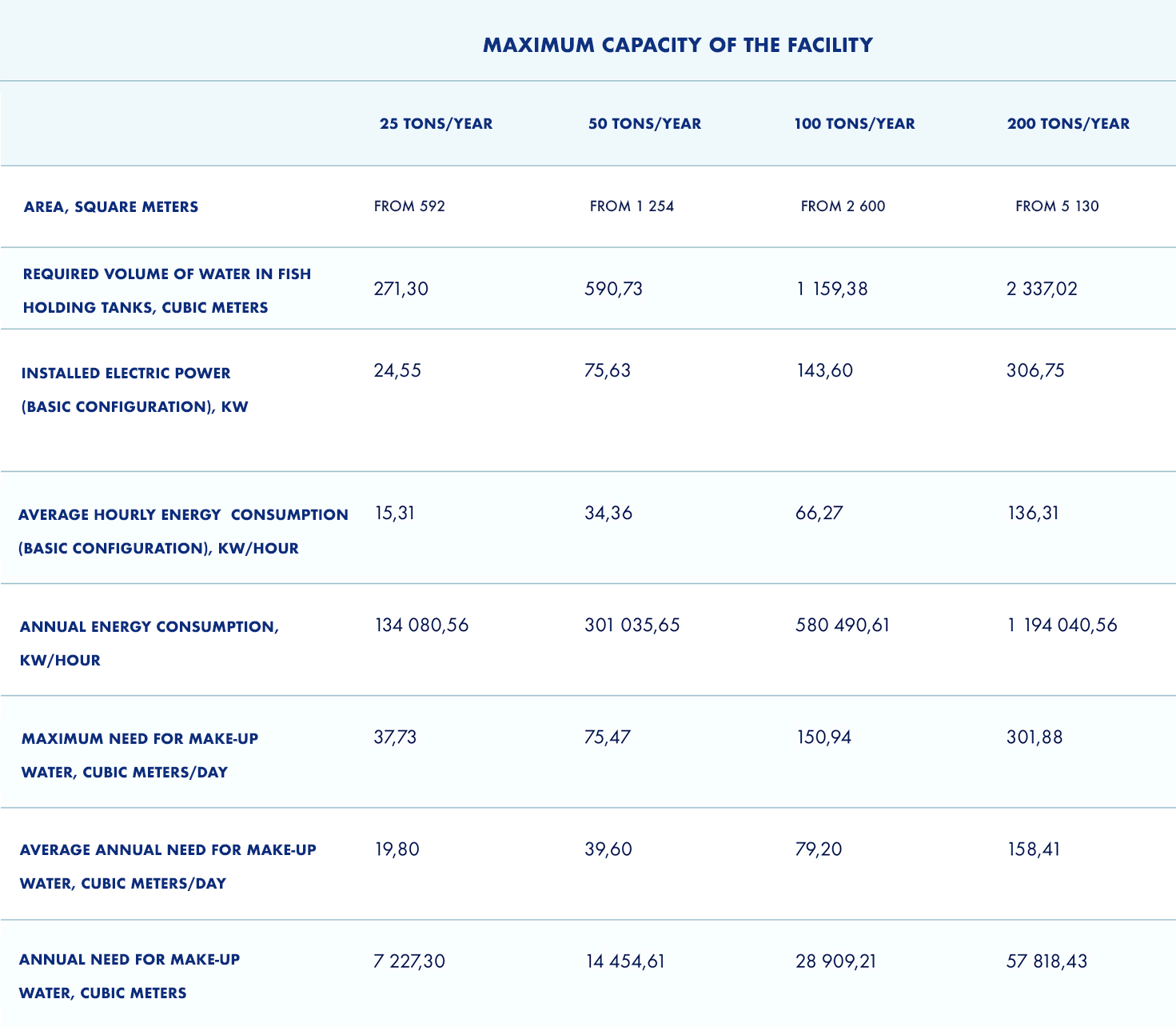

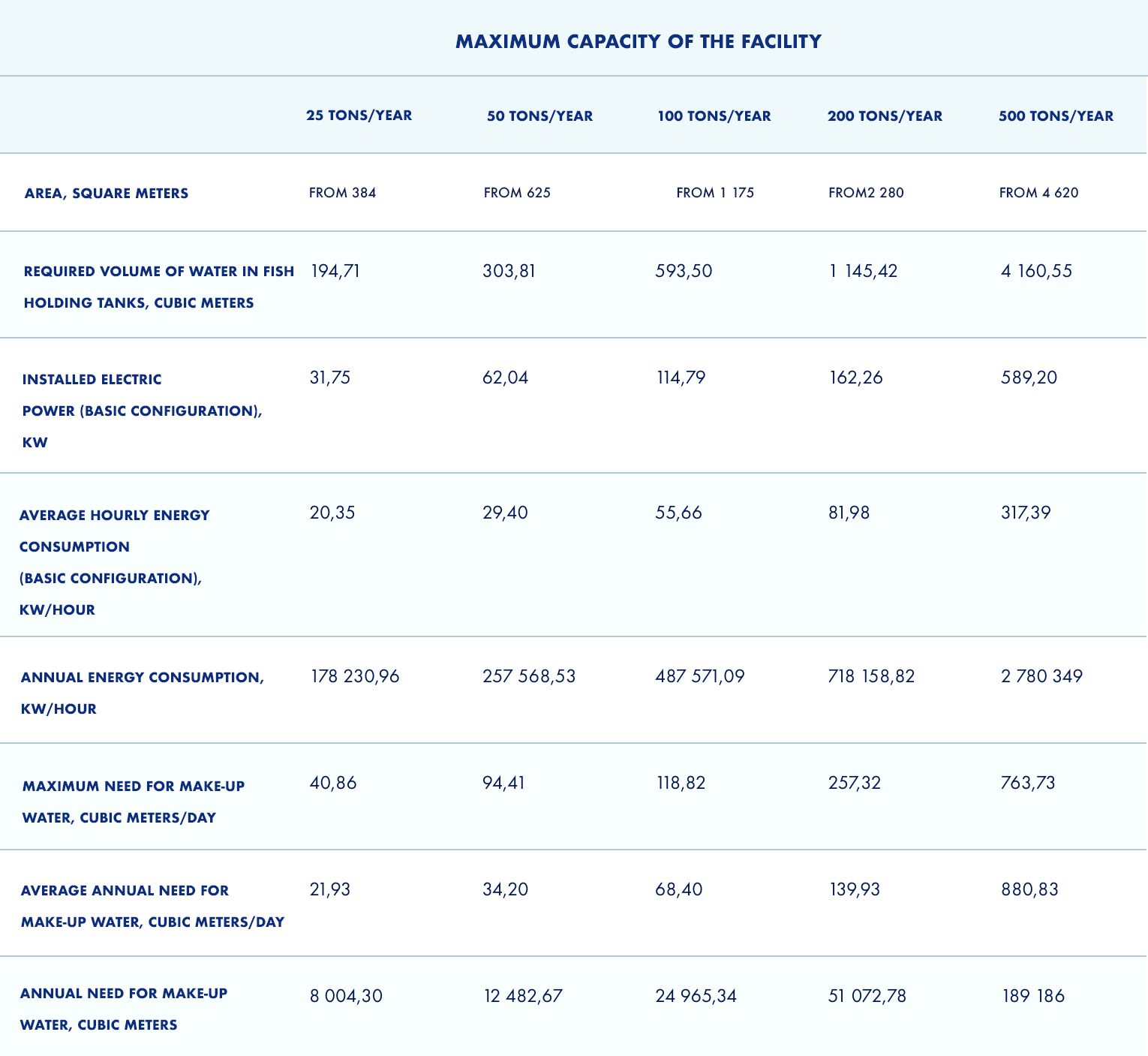

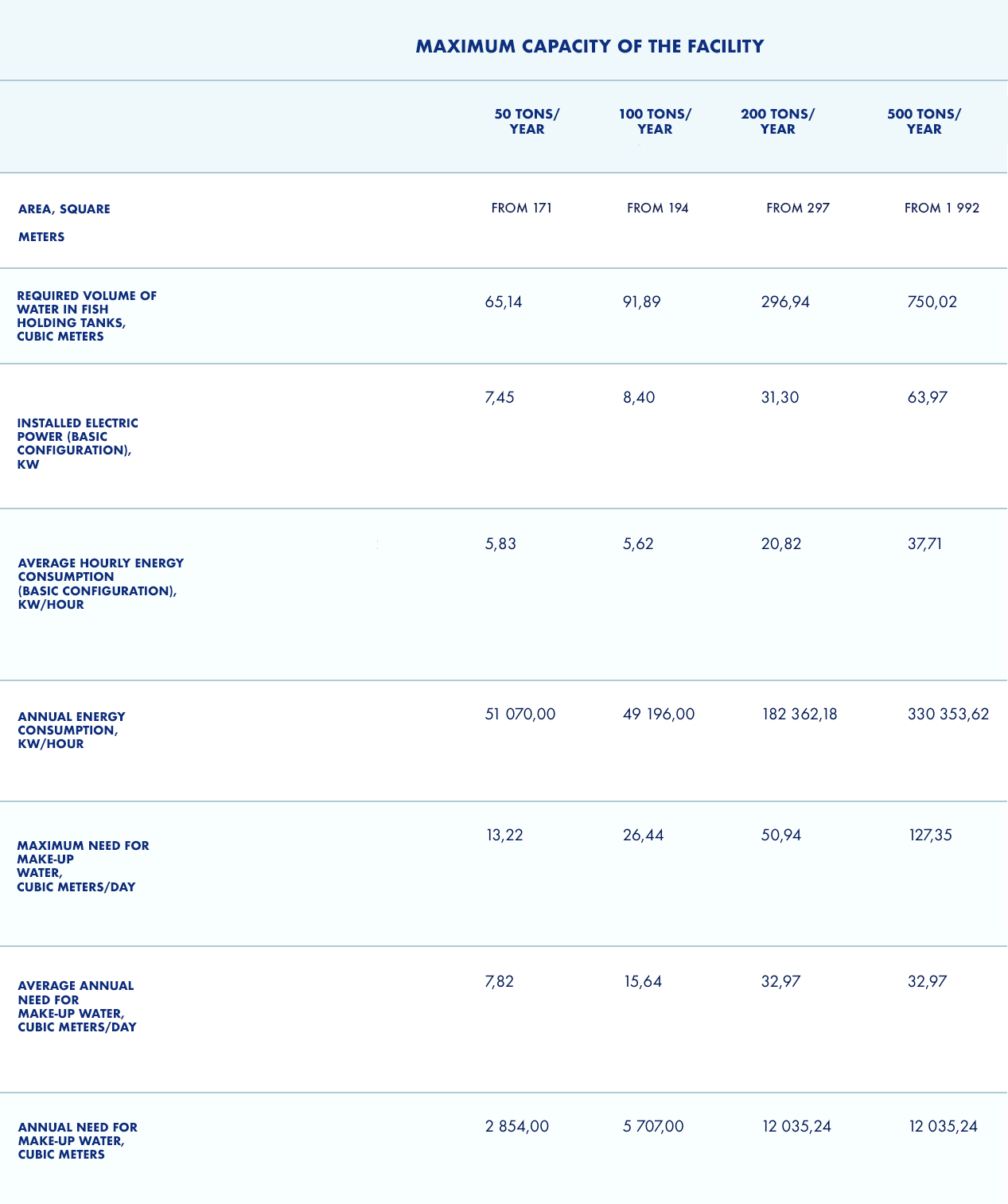

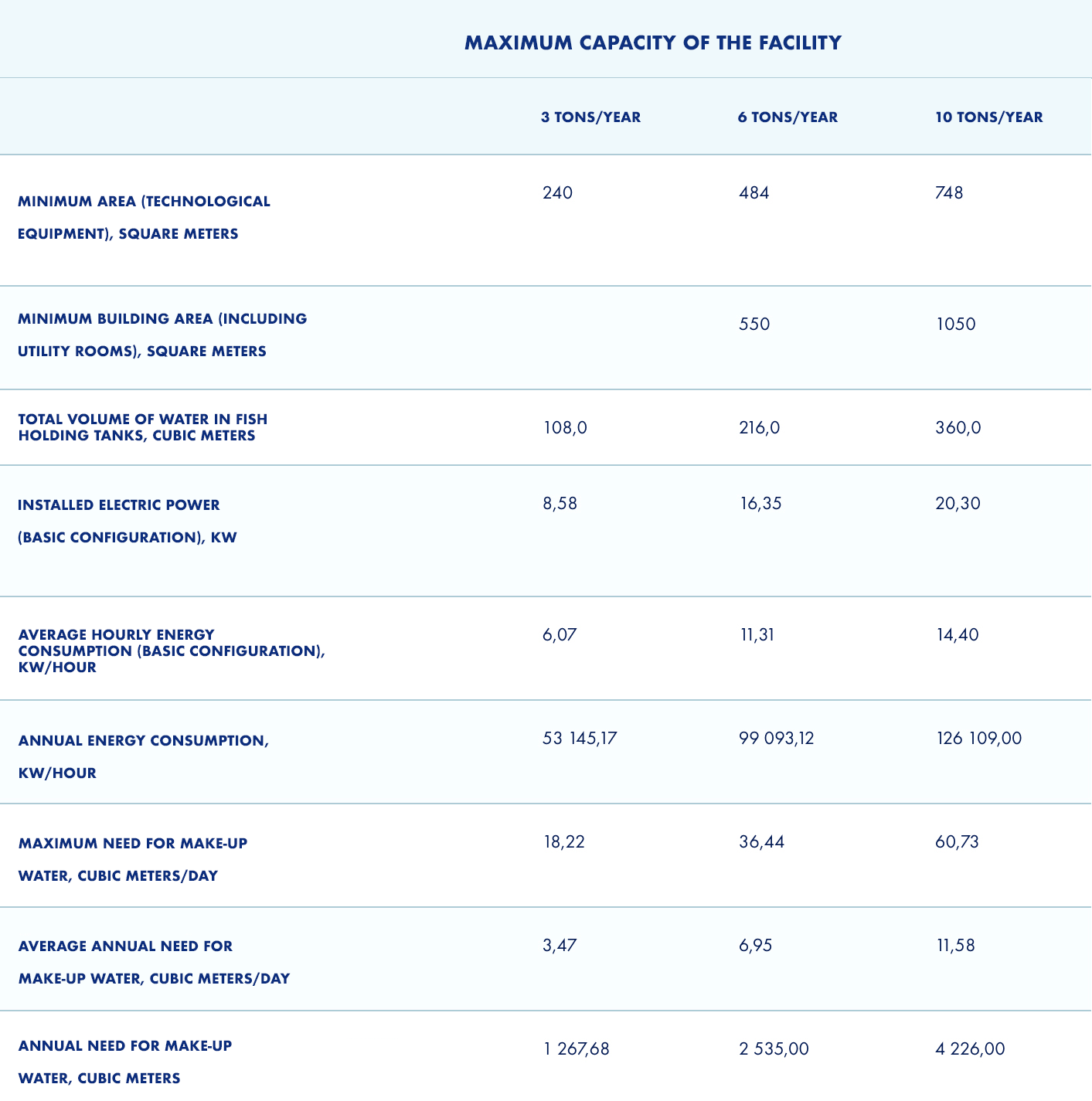

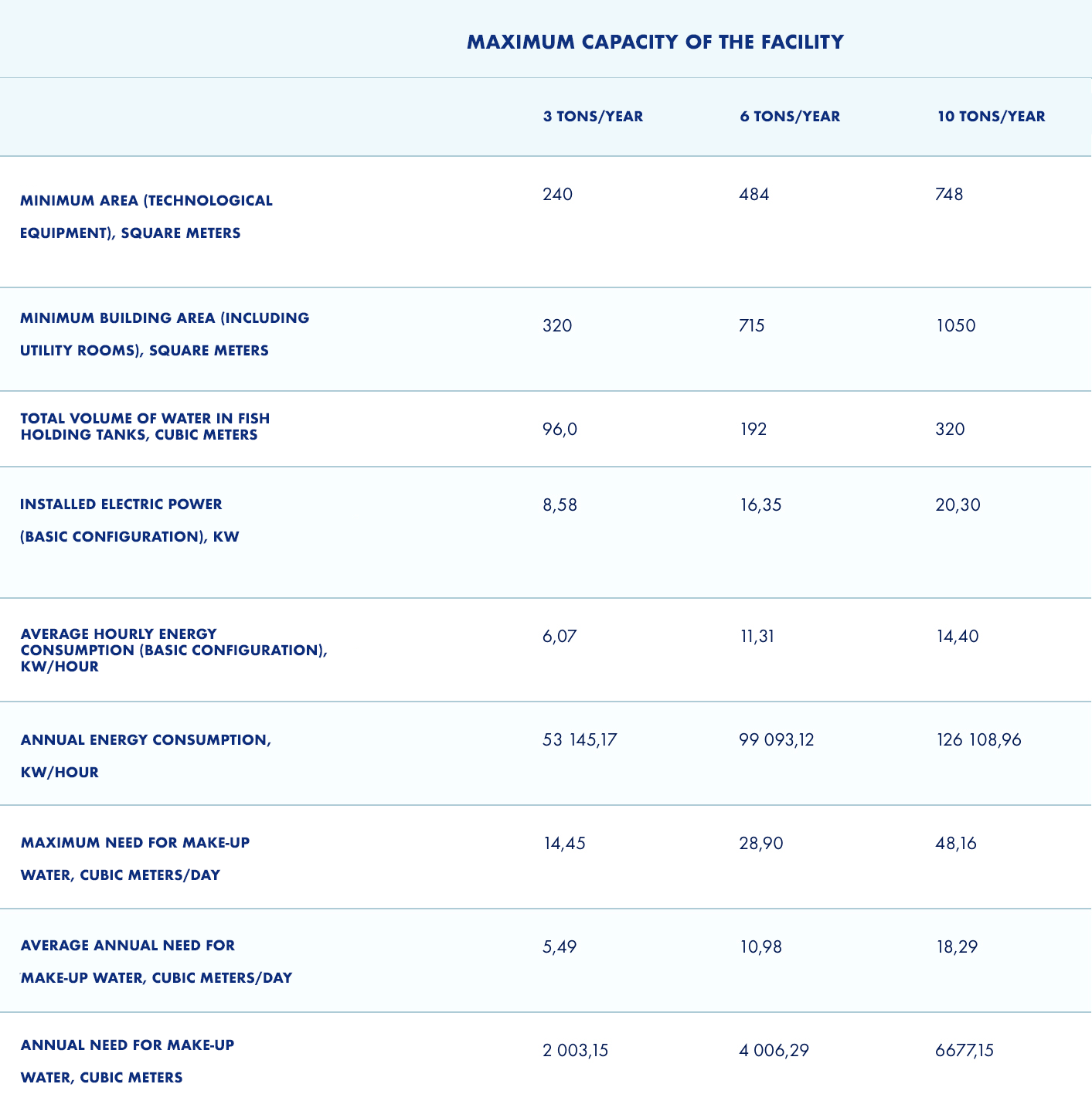

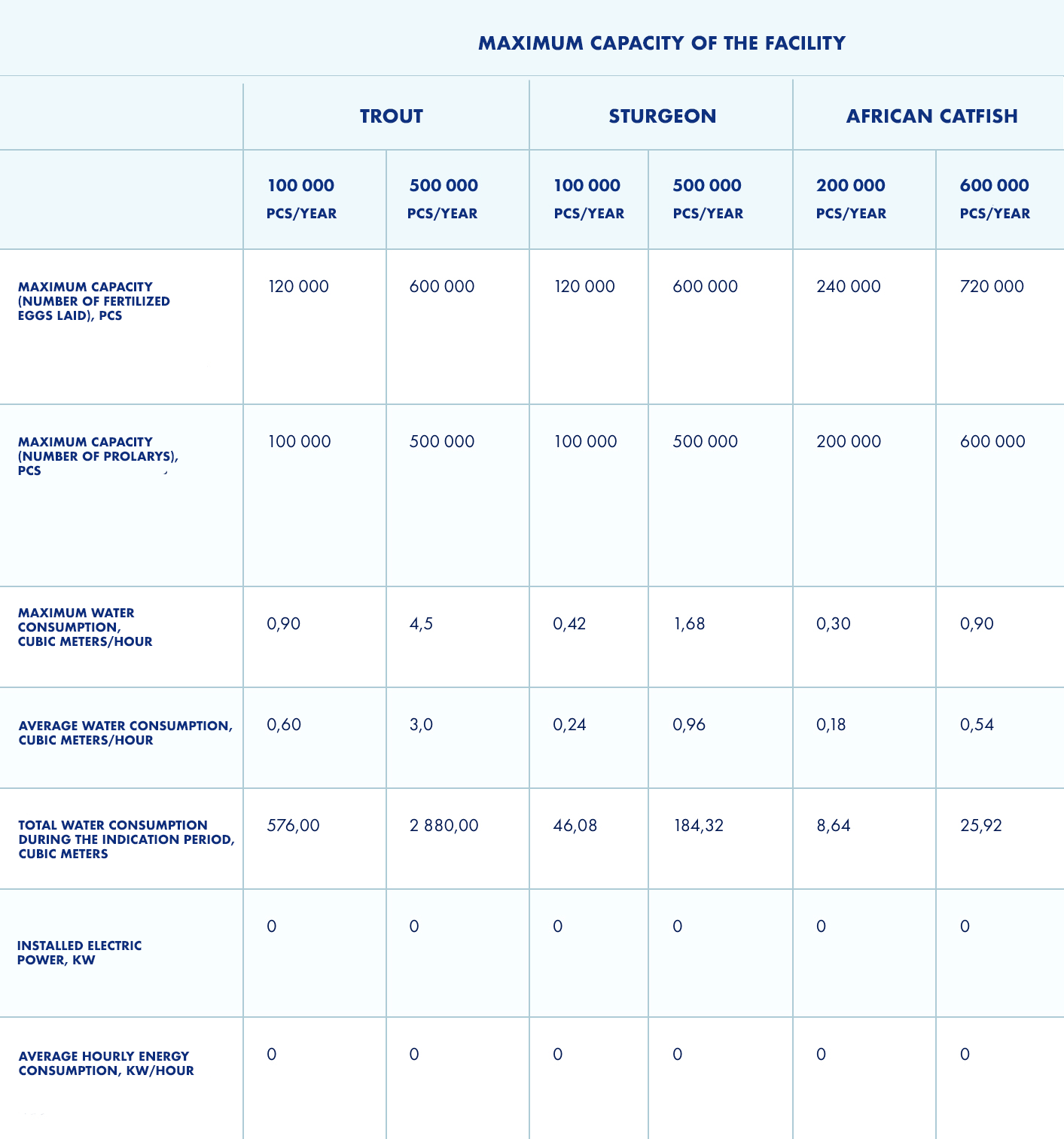

- Site and building requirements

- Equipment technical characteristics

- Other information

By clicking "Send request form" button, you agree to the terms of the personal data processing policy

Find a suitable design

We will choose one of our ready-made designs and send you a presentation with prices and specifications

By clicking the "Send" button, you agree to the terms of the personal data processing policy

Visit the office

Here's what you're going to receive:

- Get to know the team and management personally

- Get answers to all your questions

By clicking the "Send" button, you agree to the terms of the personal data processing policy

Get a detailed presentation with a full price description and technical specifications

We have been constructing and upgrading fish farms for 10 years

We managed to start up more than 50 farms

Our customers are farming 11 species of fish

Build your own recirculating aquaculture farm (RAS)

Turn-key solution, installation all over the world from the direct equipment manufacturer

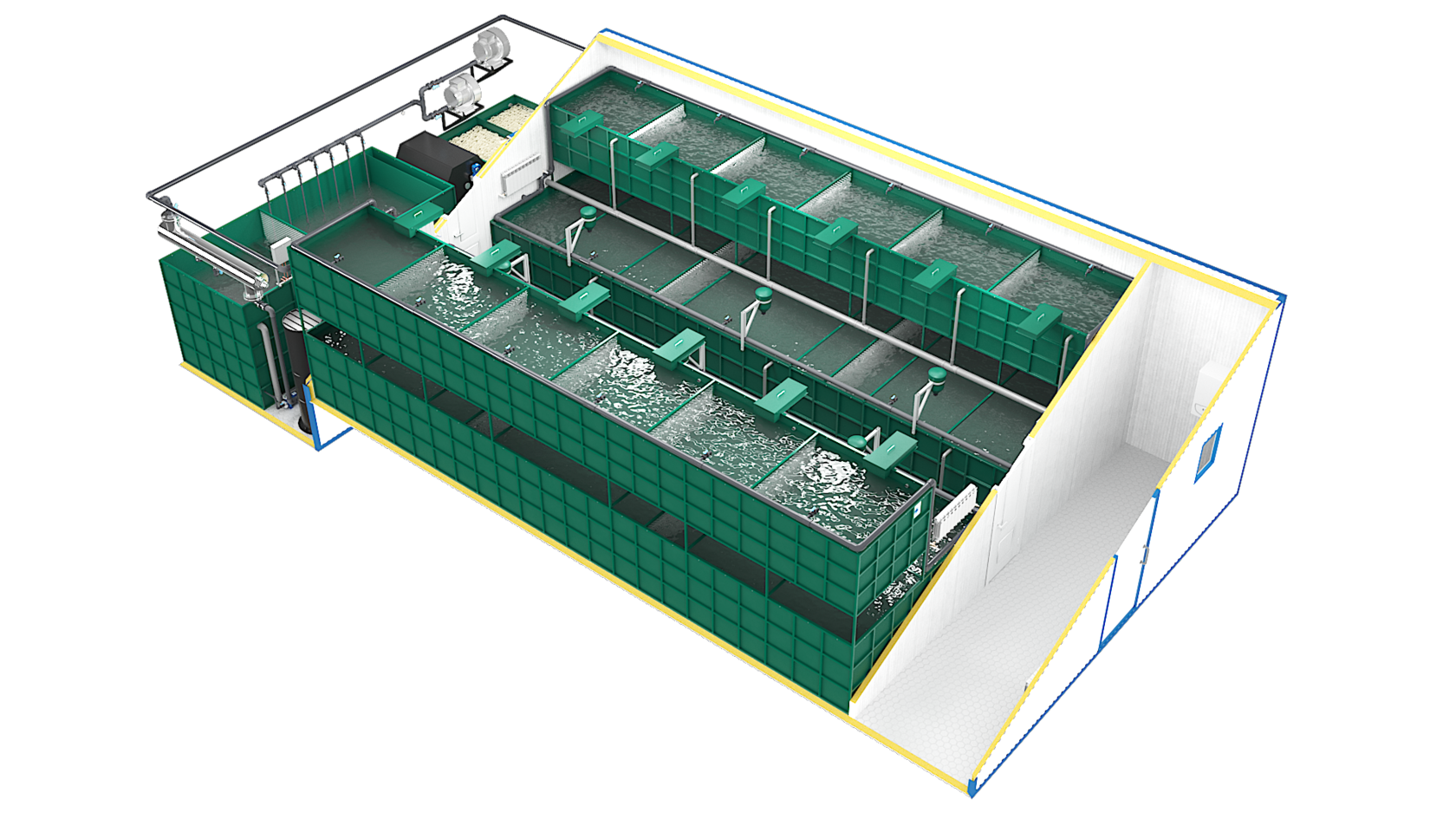

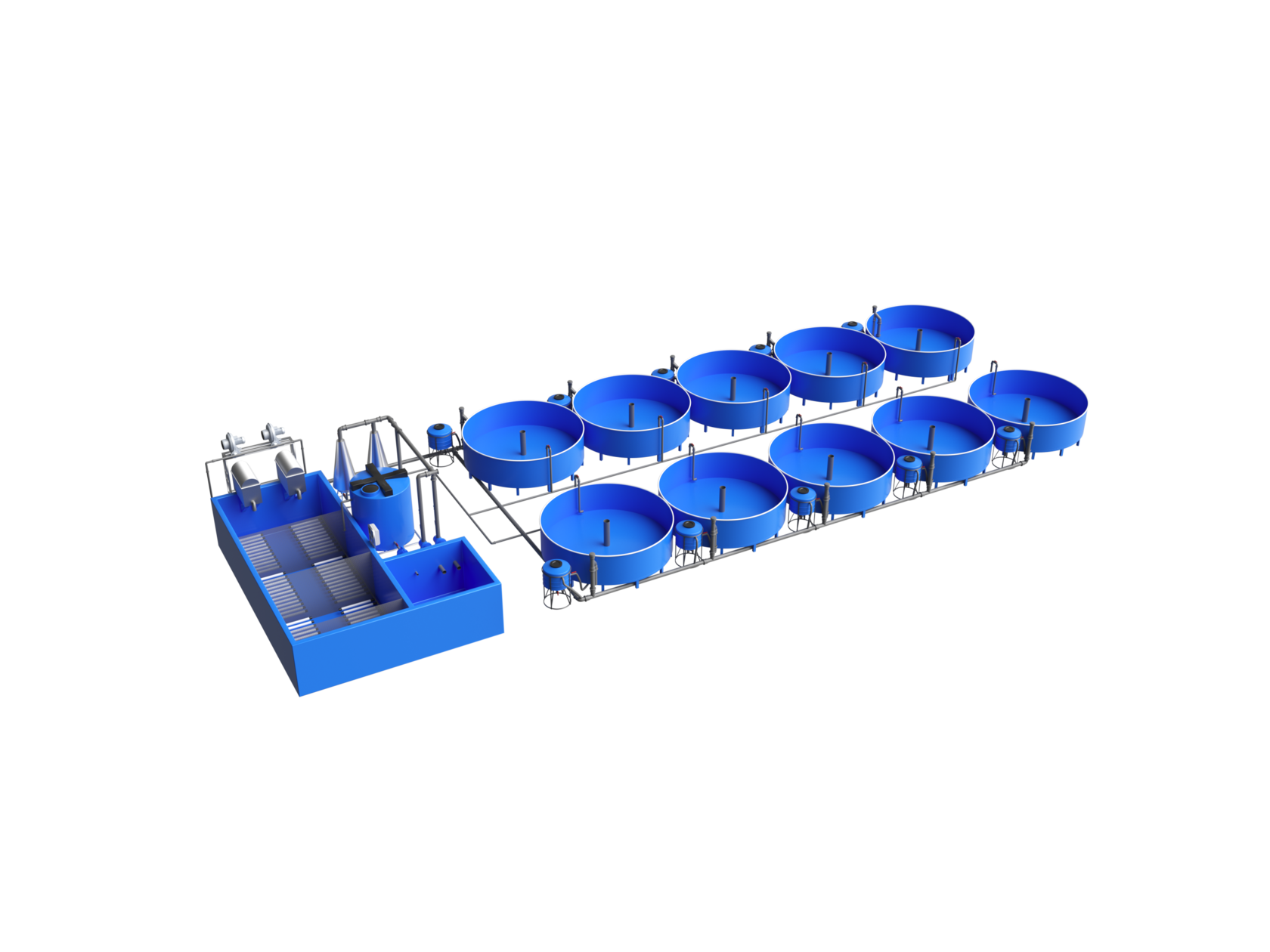

RAS is a compact automated fish farm

Fish grows 3 times faster. The farm consumes 100 times less water and takes 1000 times less area compared to pond farming

The farm is automated. It works around the clock and requires minimal staff engagement in the process

Strong sales all year round, there are no seasonal fluctuations

Organic and healthy premium quality fish without antibiotics, fed with natural granular feed

Full accounting, control and security. Closed area with a video surveillance

Invest in a stable and profitable asset

It's easy to farm fish in RAS

- The equipment is automated

- It does not require frequent purchasing of fry.

Trusted suppliers and quality assurance - Easy operation by personnel that does not require high qualification

- Minimal maintenance, it is possible to do it on your own

- The equipment is automated

- It does not require frequent purchasing of fry.

Trusted suppliers and quality assurance - Easy operation by personnel that does not require high qualification

- Minimal maintenance, it is possible to do it on your own

Fish farming plan, from fertilized eggs to growout fish

Here's what you're going to receive:

- Amount of fish tanks needed

- Total biomass

- Fish movement in the system

- Feeding

Fish farming plan, from fertilized eggs to growout fish

Here's what you're going to receive:

- Amount of fish tanks needed

- Total biomass

- Fish movement in the system

- Feeding

Fish farming plan, from fertilized eggs to growout fish

Here's what you're going to receive:

- Stages of fish farming

- Farming terms

- Stages of sorting and transferring fish

By clicking the "Get" button, you agree to the terms of the personal data processing policy

Order a callback

We know how to:

- Choose the right fish type and farm capacity

- Choose the right site and the building

- Choose the right equipment

- Choose the optimal stages of the project implementation

By clicking the "Callback" button, you agree to the terms of the personal data processing policy

Order a callback

We know how to:

- Choose the right fish type and farm capacity

- Choose the right site and the building

- Choose the right equipment

- Choose the optimal stages of the project implementation

By clicking the "Callback" button, you agree to the terms of the personal data processing policy

There is a lack of high-quality fish on the market

- Today, 60% of the world's fish is farmed. The volume of the global aquaculture market is growing. Its volume has already reached 300 billion dollars

- There are a lot of low-quality products and a shortage of ecological, locally (or nearby) farmed, healthy fish in the middle-price segment (6 to 15 USD per kg)

- Aquaculture provides 1/3 of the total global volume of fish food products. During the last decade the amount of farmed fish has been increasing by 7−10% annually. The capacity of existing fish farms is not enough to fully cover the needs of the market

- More than 50% of fish farms are using RAS technology

Supply customers with ecological, healthy and premium quality fish

- 100% healthy fish without parasites (mechanically and biologically treated water – disinfected 24 hours a day with ultraviolet and ozone + healthy fry)

- Natural feed without antibiotics (high quality extruded feed with optimal composition for each specific type of fish)

- The best possible muscle tone of the fish (continuous circulation of water in fish holding tanks, water circulation speed control)

- Fish doesn’t smell like mud (ozonation + purging completely remove any fish smell)

- 100% healthy fish without parasites (mechanically and biologically treated water – disinfected 24 hours a day with ultraviolet and ozone + healthy fry)

- Natural feed without antibiotics (high quality extruded feed with optimal composition for each specific type of fish)

- The best possible muscle tone of the fish (continuous circulation of water in fish holding tanks, water circulation speed control)

- Fish doesn’t smell like mud (ozonation + purging completely remove any fish smell)

The equipment is successfully operated by 57 farms

Capacity - 500,000 of fry.

Area - 200 sq. m

Area - 8000 sq. m

Full cycle "caviar to caviar"

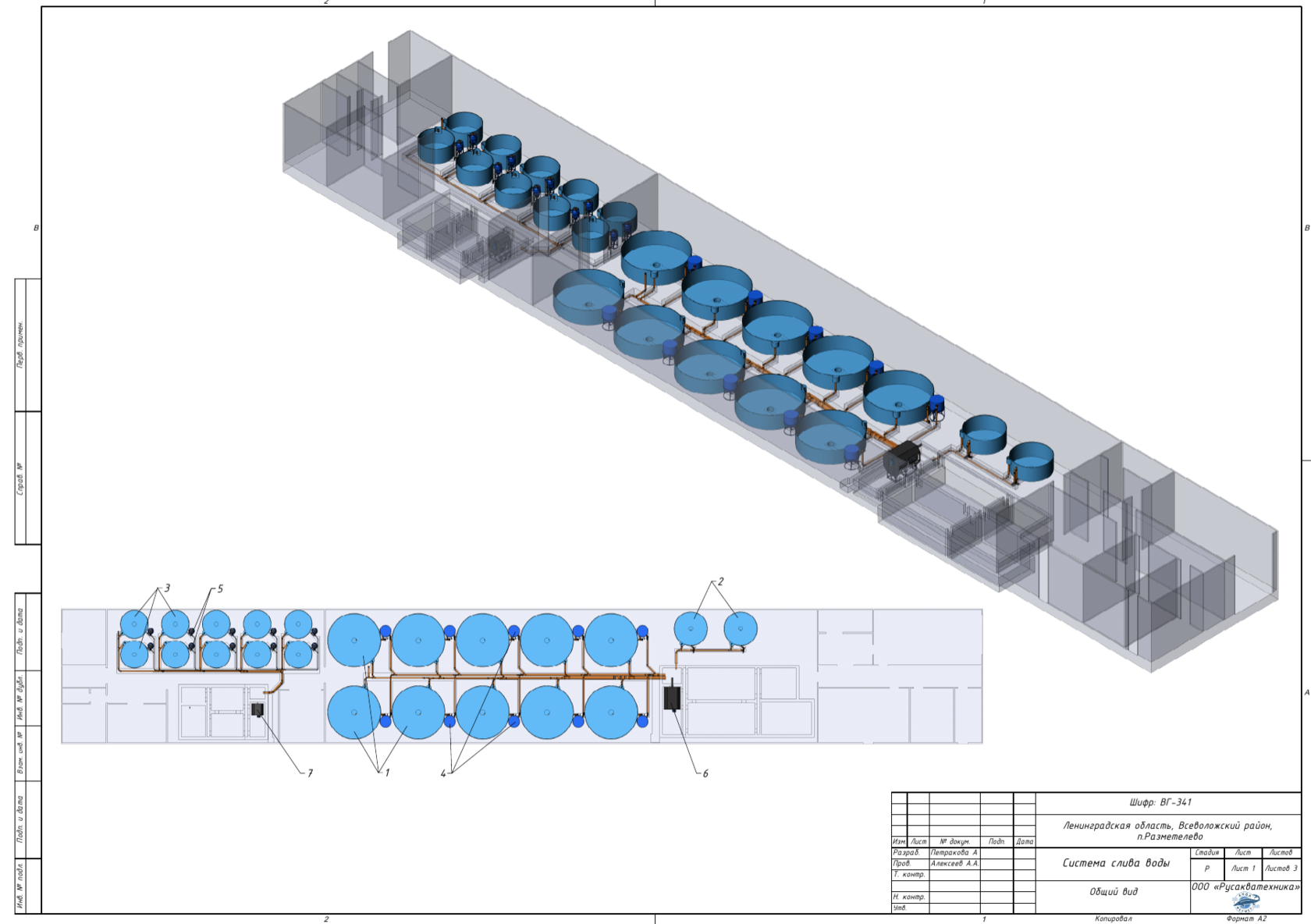

Area - 2400 sq. m

Cultivation of sturgeon from fry of 3 gr to growout fish of 2-3 kg.

It includes 24 fish holding tanks of 40 m3 each, water treatment and recirculation system

Area - 200 sq. m

From fry of 3 gr to growout fish weighing 1.5 to 2 kg

Includes water treatment, recirculation system and fish holding tanks

Area - 90 sq. m

Fish farming from fry of 10 gr to growout fish of 1.5 to 3 kg

Includes water treatment, recirculating system and fish holding tanks

Area - 200 sq. m

From fertilized eggs to fry of 100 to 200 gr weight

Area is 200 sq. m

Area - 178 sq. m

Visit the office

Here's what you're going to receive:

- Get to know the team and management personally

- Get answers to all your questions

We will launch your farm from the first sketches to growout fish

— On-site consultation

— Detailed analysis of the site, building, and utility lines with an expert conclusion

— Expert assessment of the possibility of building a fish farming facility

— Reasonable use of existing infrastructure

— Optimal, efficient arrangement of equipment

— A balanced set of equipment (only what is really needed)

— Production plan and fish transfer calculations

— Assessment of capital and operational costs

— Reducing the real fish cost and payback period

— Verification of completed construction works for correctness in relation to provided technical requirements

— Compliance with production deadlines

— Manufacturer's warranty up to 3 years

— Providing equipment delivery support…. with the guarantee of safety

— Delivering equipment to the facility on time

— Installation by professional team equipped with all required instrument

— Providing leak-test, test run and checking that the facility reaches maximum capacity

— Launching the biofilter

— Providing warranty for the accomplished installation works - up to 3 years

— Assisting with the acceptance of fry from the supplier and its safe delivery to the facility

— Helping with stocking and monitoring fish adaptation in the fish holding tanks

— Support with leveraged finance

— Expansion Project

— Turnkey Implementation

Specific custom solutions

- Reconstruction and upgrade of existing enterprises

- Assistance in obtaining the state support

- Bioplanning for the construction of RAS facilities

- Undergoing state and non-state examination

- Production and configuration of individual fish farming equipment

- Consulting in the field of fish farming and RAS

Efficient use of investments

- We effectively design farms (as compact as possible)

- We will think over technical solutions, bypassing the pitfalls. You will save time and money by avoiding mistakes and rebuilding

- The equipment has been tested at more than 50 farms. It doesn’t require any improvements and constant maintenance

- We will produce equipment at manufacturer’s prices without excess payments

Custom solutions for all major fish species

German water treatment technology

Work directly with the equipment manufacturer

- PH adjustment systems

- Drum Filters

- Fish holding tanks

- Biofilters

- Live Feed Blocks

- Bead filters

- Swirl filters

- Degassers

- Incubation equipment

- Oxygen concentrators

- Ozone retention columns

- Ozone generators

- Oxygen generators

- Feeder tanks

- Thin-layer sumps

- Control panels

Become a representative

BECOME AQUAFARMER REPRESENTATIVE IN YOUR COUNTRY

By clicking the "Send" button, you agree to the terms of the personal data processing policy

A full-fledged team of more than 40 professionals

- The founder of the company. CEO

- Anton Pelcher

- Founder and owner of the Aquafarmer company;

- Leading expert in the field of RAS fish farming systems in Russia and the CIS;

- Water treatment systems engineer;

- More than 10 years of experience in designing RAS, direct-flow systems, and circulating water supply systems;

- Designed more than 30 RAS facilities and developed more than 100 projects as part of the Aquafarmer team;

- More than 20 completed projects in the examination and upgrading of existing facilities;

- Link to YouTube channel

- The founder of the company. Technical Director.

- Launched more than 50 fish farms as part of Aquafarmer team

- Developed about 100 units of new equipment

- Founder's TikTok channel

Customer Care Department

Engineering team

Production

Installation and service team

Our customers recommend us

We are trusted by the professional community

- PUBLIC AUTHORITIES PORTALAquafarmer takes one of the leading positions in the field of aquaculture and fish farming equipment. Many years of experience in designing…

READ IN THE ORIGINAL

READ IN ENGLISH - FISH UNIONRosrybolovstvo reported that according to the results of the first half of 2021, Russian salmon production in aquaculture increased by 57% from 49.2 thousand tons to 77 thousand tons.

READ IN THE ORIGINAL

READ IN ENGLISH - MINISTRY OF

AGRICULTURE

OF PRIMORSKY REGIONMinistry of Agriculture of Primorsky regionThis company has been operating on the market of design and construction of fish farms for more than 10 years, more than 50 farms have been built and reconstructed.

READ IN THE ORIGINAL - YARNEWS ONLINE MEDIA. YAROSLAVL CITIZENS ARE PROMISED TO BE FED WITH AFRICAN CATFISHYaroslavl entrepreneur Vladimir Salakhutdinov has launched a farm for farming African catfish The special fish holding tanks contain fry that will reach the size of growout fish in 4 to 6 months.

READ IN THE ORIGINAL

READ IN ENGLISH MADE BY OUR COMPANY

The Dalai aquafarm has been started up in TuvaThe aquafarm was started up on the basis of the Dalai agricultural consumer processing cooperative. They became the winners of the competition of the Ministry of Agriculture and Food of the Republic of Tatarstan for the provision of state support to business entities operating in the field of fish farming.

READ IN THE ORIGINAL

READ IN ENGLISHVESTI NOVOSIBIRSK

A resident from Berdsk learned how to farm African catfishAfrican catfish lives in a private garage rather than in the pond, the sea, in Ob river. A resident from Berdsk is developing a new business for our region. Pedestrian fish is a fish that can breathe on land. How else can Africans surprise Siberians?

READ IN THE ORIGINAL

READ IN ENGLISH- THE OFFICIAL PORTAL OF THE STATE AUTHORITIES OF THE JEWISH AUTONOMOUS REGIONAquafarmer — RusAquaTekhnika LLC, takes one of the leading positions in the field of aquaculture and manufcaturing equipment for fish farming.

READ IN THE ORIGINAL

Aquafarmer takes one of the leading positions in the field of aquaculture and manufacturing of fish farming equipment. Many years of experience in designing and manufacturing equipment allows us to implement complex infrastructure projects in a short time with a high level of quality. The guarantee of this result is 100% top-down of processes by our company from the development of an business model to the design, manufacturing and installation of all elements of the engineering system. Today, the company has more than 50 implemented fish farms in Russia, the CIS and neighboring countries, including not only large industrial facilities, but also small start up farms. The company is actively involved in the development of aquaculture in the regions, including in government support programs.

The technology of fish farming and seafood indoors (RAS or recirculating aquaculture system) in Russia is not so developed. Although we have successful projects all over the country like in the Moscow region, Karelia, in the south of Russia, in the Krasnoyarsk region. Such aquaculture farms do not need hectares of land and access to open water. The area of the smallest fish farms is only 40 square meters. The most suitable species of fish for growing in RAS are sturgeon, trout, African catfish. The main advantages of RAS are the year-round farming of fish and a quick increase in its weight.

The Fish Union supports the development of aquaculture in Russia. We consider this part of the fish farming complex to be the most promising. We also cooperate with manufacturers of equipment for water farms.

Aquafarmer is one of the leaders of the market in designing and manufacturing equipment for fish farming in RAS. Within the framework of cooperation, the company provides significant discounts to members of the Fish Union and advises free of charge on RAS.

As IA REGNUM notes, the future enterprise itself is located in Yaroslavl in Zhuravleva street. At the same time, earlier farming African catfish was planned to be organized in the village of Vakhrushevo, Rostov district. An industrial facility was intended to be opened for the production of 1,500 tons of live fish per year.

The construction started in September 2017 but the opening dates of the farmplant were repeatedly shifted. The production of African catfish was consistently planned to begin in September 2018, the first or second quarter of 2019 and the first half of 2020. At the grand opening, Sergey Shinkarev, CEO of Inagrobio LLC, reiterated that the company had "started implementing" the project of farming African catfish in the Rostov region. The farm plans to produce 1,250 tons of live fish per year.

Representatives of the Department of Agriculture announced measures to support new production in Yaroslavl. The entrepreneur is promised to be provided with state support as reimbursement of part of the costs incurred for the purchased equipment in the amount of up to 30% of its cost. He is also promised to be given with a preferential loan for the purchase of fish planting material and specialized feed. The loan will be provided by the Fund for the Development of Industry and Agro-Industrial Complex of the Yaroslavl region.

The aquafarm is located on the area of the former Kyzyl fish factory. The founders of Dalai Agricultural consuming processing cooperative acquired the facilities from Tyvarybkhoz LLC fish processing workshop in Kyzyl in 2014.

The contract for the supply and installation of equipment for the aquafarm was concluded with a specialized company - RusAquaTekhnika LLC, located in Moscow. A lot of equipment is needed to farm grouout fish. It includes water recirculation system, a pre-sale preparation tank, hydrocyclones, water heating system, a manual laboratory, a biofilter launch kit and other. At the beginning of October this year, aquatic biological resources were delivered from the Omsk plant Borodino. It includes 500 pieces of sturgeon fry, each weighing from 50 to 70 grams.

For the effective implementation of the project, representatives of Dalai Agricultural consuming processing cooperative studied the management of growout fish farming on the basis of Rybkhoz LLC in Novosibirsk in 2017. Also, repairs of electricity, heat, water supply, major repairs of premises for the installation of equipment were carried out at the expense of the cooperative's own funds. The aquafarm is located on the area of the former Kyzyl fish factory. The founders of Dalai Agricultural consuming processing cooperative acquired the facilities from Tyvarybkhoz LLC fish processing workshop in Kyzyl in 2014.

The activity of Dalai Agricultural consuming processing cooperative is not limited to the aquafarm. in 2015, according to the Ministry of Agriculture and Food of Tuva, representatives of the cooperative received a fishing site on the Ushpe-Khol lake in the Todzhinsky district for a period of 15 years as per the results of the competition. Every year they use the quota for the harvesting (catch) of aquatic biological resources in the amount of 27 tons (pike is 7 tons, perch is 10 tons, roach is 10 tons). It is are processed on the fish processing plant of the Dalai Agricultural consuming processing cooperative. The range of products of the fish shop includes dried, salted, smoked fish (sea and lake fish).

Igor Chernov, owner of an experimental fish farm says "Mucus is a protective film that detains all pathogens and microorganisms. In fact, when examining the meat of this catfish, no pathogenic microorganisms were found."

Igor Chernov has never known so much about fish. He ran different kinds of business like petroleum products and seedlings. Catfish is a new thing. There is no one to consult with. I have not met such farms in the field. Like-minded people from Moscow help. Igor has fifteen hundred fish in three gish holding tanks. Water is kind of muddy at first glance, but is treated every hour with the help of the filter.

Olesya Gerasimenko says "African catfish is incredibly tenacious. It can easily survive one or two hours without water. In natural conditions they can move overland due to bending movements and fins from a dried-up reservoir in search of water."

On land, the catfish is able to breathe with a special suprabranchial organ. It's like a lung. But without water, the fish will die, on average, in a day. African catfish is generally unpretentious. It needs minimal care andgrows quickly. In 4 months it grows up to one and a half kilo.

Igor Chernov, owner of an experimental farm says "Its meat is very tender and juicy without an obvious taste of fish. Even if it's cooked, you will doubt what kind of meat it is. Someone says it's like a veal or chicken. There is no smell of fish."

Residents of Novosibirsk and Berdsk will be able to taste the African delicacy soon. Igor suggests looking for his fish in restaurant menus.

Find out more about RAS fish farming business

Local aquaculture associations trust us

- EURASIAN AQUACULTURE ALLIANCEThe main goals and objectives of the Eurasian Aquaculture Alliance are the implementation of effective support for fish farming and the unification of industry representatives into a single self-regulating organization.

- ASSOCIATION OF PEASANT (FARMER) FARMS AND AGRICULTURAL COOPERATIVES OF RUSSIA (AKKOR)Established in January 1990, it is a non-governmental non-profit organization.

UNION OF STURGEON FISH FARMERS. NON-PROFIT ORGANIZATION OF FISH FARMERS.

Our partners

Learn more about RAS and our team, visit social networks

Our contact information

Office address: Leninskaya Sloboda str., 26, bld. C, Business Centre “Omega-2”, office 437.1, Moscow

Phone: +7 (495) 984 46 17